Diagnostic software for

insulating fluid test data.

Push beyond conventional paradigms to a more correct interpretation.

Dissolved gas is not the problem

Interpreting DGA data is a three-step process

Does a fault exist?

Recent advancements in DGA interpretation, including:

- Using fault energy indices to simplify the analysis,

- Accounting for gas loss,

- Focusing on gassing events, and

- Applying reliability statistics to relate DGA data with transformer failures identifies problematic transformers earlier and significantly reduces false alarms.

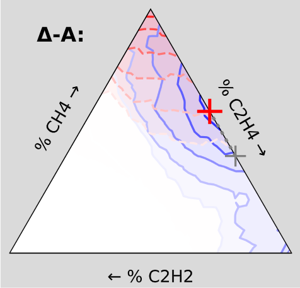

What type of fault is it?

The Duval triangles are tried and true fault type diagnostic tools, but can require the application of multiple triangles to distinguish particular faults that require interpretation of more than three hydrocarbon gases.

Using all five hydrocarbon gases, the 4-Simplex provides a nuanced result that allows for understanding mixed fault types, and has proven to be more reliable than the Duval pentagon.

How severe is the fault?

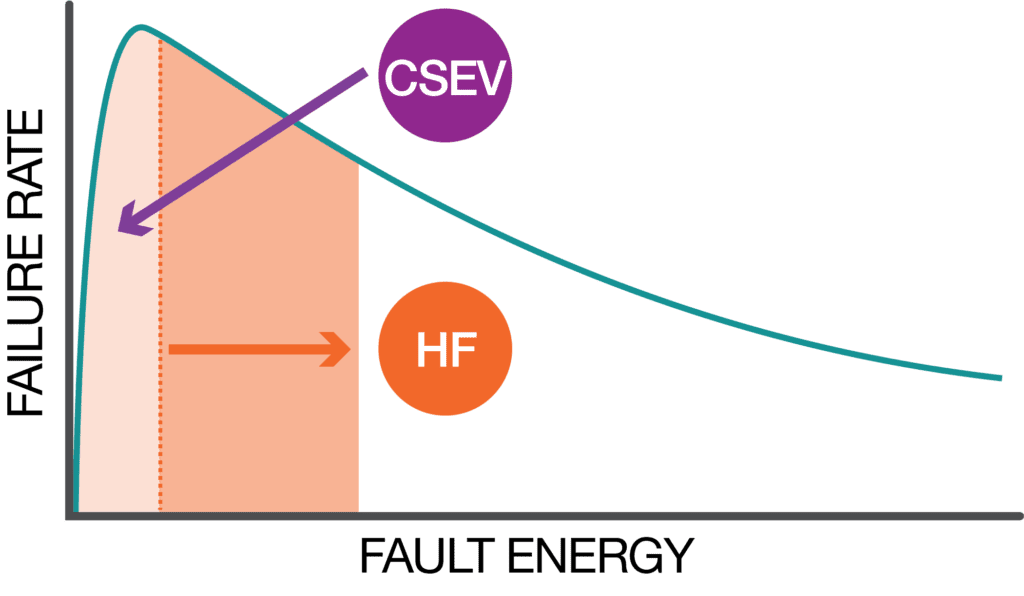

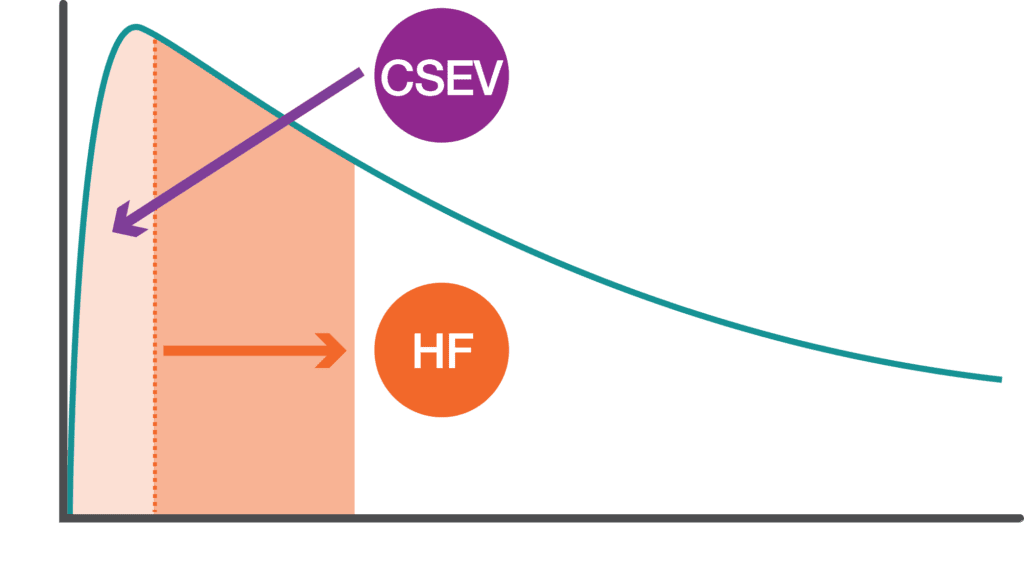

Reliability-based DGA is based on a statistical model built from transformer reliability data, including failure events. A transformer’s fault energy index is compared to the model to provide two measures:

- Cumulative Severity (CSEV) indicates the percentage of transformers that are gassing that would fail prior to transformer of interest; and

- Hazard Factor (HF) indicates the probability of failure over the next year if gas production continues at the current rate.

Hazard Factor is a more precise severity assessment than the simple green/yellow/red status codes used by conventional methods, and thereby enables fleet prioritization optimized for deploying maintenance resources.

The most correct interpretation of DGA available on the market!

Reliability-based DGA is a major development in dissolved gas analysis and transformer monitoring software – and will help you increase reliability, optimize maintenance, and maximize ROI, while reducing the risks of an unforeseen catastrophic transformer failure.

Ensure transformer and grid health

through Reliability-Based DGA

Gassing history indicates how fortunate the transformer is to have survived to this point.

Indicates the rate, in percent per year, at which the risk of failure increases.

Featured DGA Articles

A major US utility is already using Reliability-based DGA. Find out how it helps identify and flag at-risk transformers so they can implement effective maintenance strategies.

Advanced Moisture Assessment for Transformers

In this NETAWorld whitepaper, Dr. Jim Dukarm discusses the exchange of water between the paper insulation and oil, and that periodic moisture assessment is highly advisable for power transformers because excessive moisture in oil and paper insulation can accelerate degradation.

Frost & Sullivan recognizes Delta-X Research for best practices.

Frost & Sullivan recognizes Delta-X Research for innovation.